The Making of…

the Royal Berkeley Emperor Tourbillon

The teeming yet idyllic nature of London’s Berkeley square has been quintessentially captured in the Berkeley Royal Emperor Tourbillon. This bespoke watch is a supreme illustration of Backes and Strauss’ continuous inspiration that is drawn from London’s iconic architecture.

Finished with 1,080 diamonds, it is an ultimate testament to Backes and Strauss’ endeavour for innovation using historically unprecedented expertise. In its conceptual design, this unique piece has undergone a complete skeletonization, keeping only the essential movements needed for the bespoke manual winding skeleton tourbillon in the timepiece, which is framed inside the square shape of the case similar to London’s Berkeley square. This Luxury watch exhibits a simple yet extraordinarily complex design which demonstrates how effortless a master’s intricate craftsmanship can look when they have executed it.

The process of making the timepiece

idea

Vartkess Knadjian wanted to create a unique and exceptional collection of 5 bespoke skeleton tourbillon timepieces.

prototyping

By way of a 3D printer, a prototype of the timepiece was created. Once the prototype was approved by Vartkess and his team, its production has started.

sourcing gold

The gold was then ordered from the refinery. For the case, a block of gold was required to shape and carve according to technical drawings by a CNC (Computer Numerical Control) machine. The CNC machine requires a technical team to program to exact measurements. For the bracelet, bars of gold were required for the goldsmith to create lines of gold for the setting of the diamonds which were then linked together by hand.

sketches

Sketches were taken to the horological department who assessed how to bring to life these timepieces for Backes & Strauss.

diamond sourcing

Vartkess then coordinated diamond processes: hand selecting, assessing how they will each be individually set, buying from different sources across the globe.

preparing the case

Meanwhile the precisely measured crystal glass for the back and front was ordered.

measurements

Here the technical design was composed. This is where all techniques required are assessed and measured precisely.

diamond polishing

Varying teams of diamond polishers then began the polishing process, ensuring that every accurate measurement of the diamonds was perfected and respected.

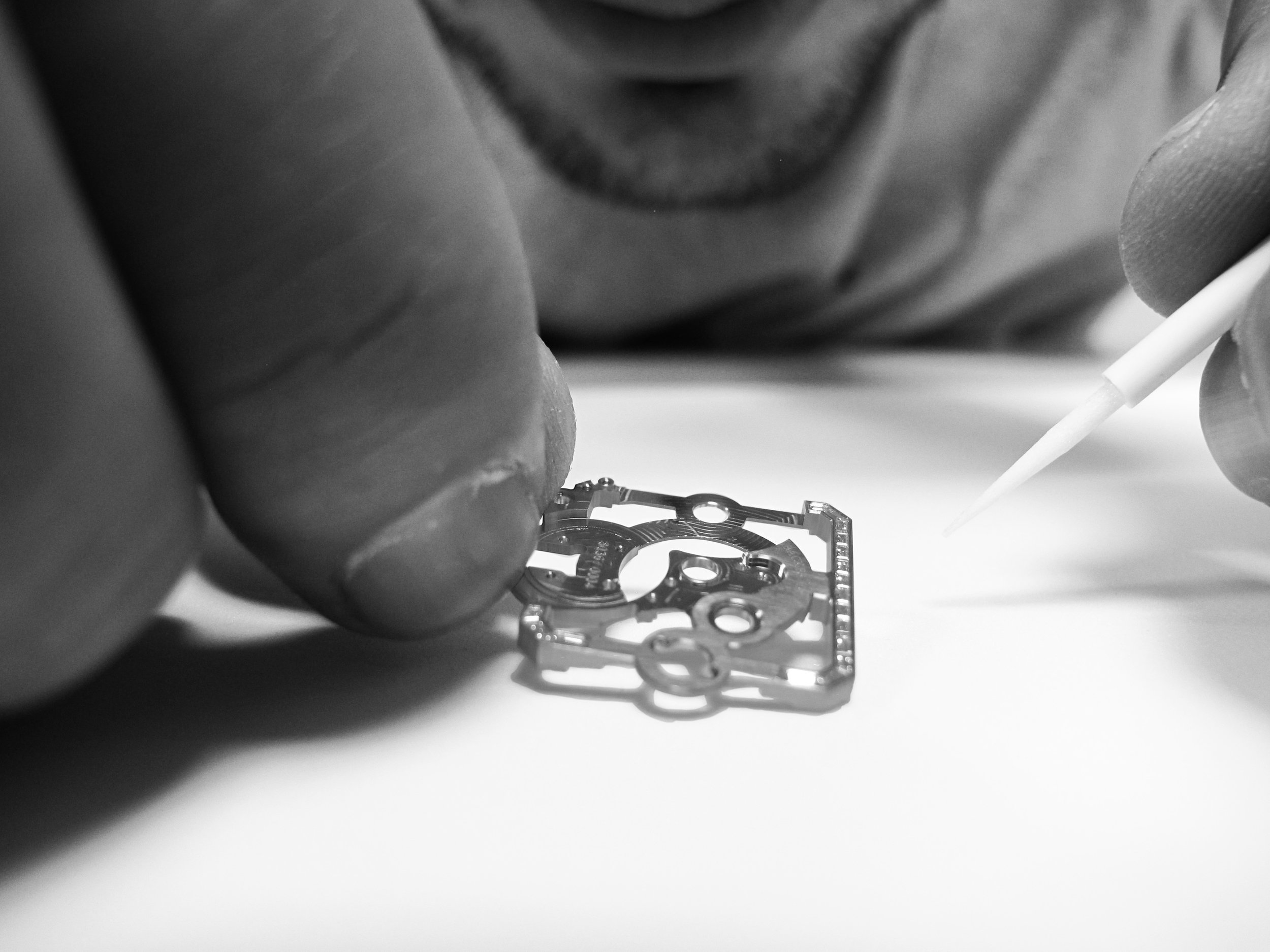

diamond setting

Various teams of dedicated diamond setters worked on the setting of the timepiece: the inner case, the case, the bridge. The most important and difficult setting was that of the 60 baguettes on the bridge holding the movement to the case. These are not straight line baguettes but rather tapered baguettes cut to extreme precision with supreme care. Any damage could affect the functioning of the watch. This process was repeated for the front and back.